FAQ

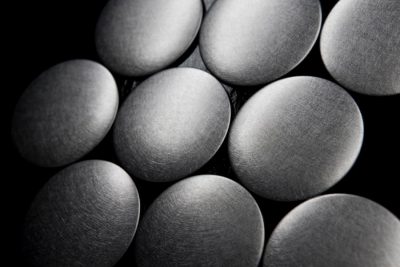

ALLOY only work with high-grade metals. Some companies will substitute high-grade metals with cheaper materials that will corrode and not last. Only ALLOY, manufacturers of the authentic solid metal mosaic tile, provides a Certificate of Origin document, which ensures only high-grade stainless steels and metals are used.

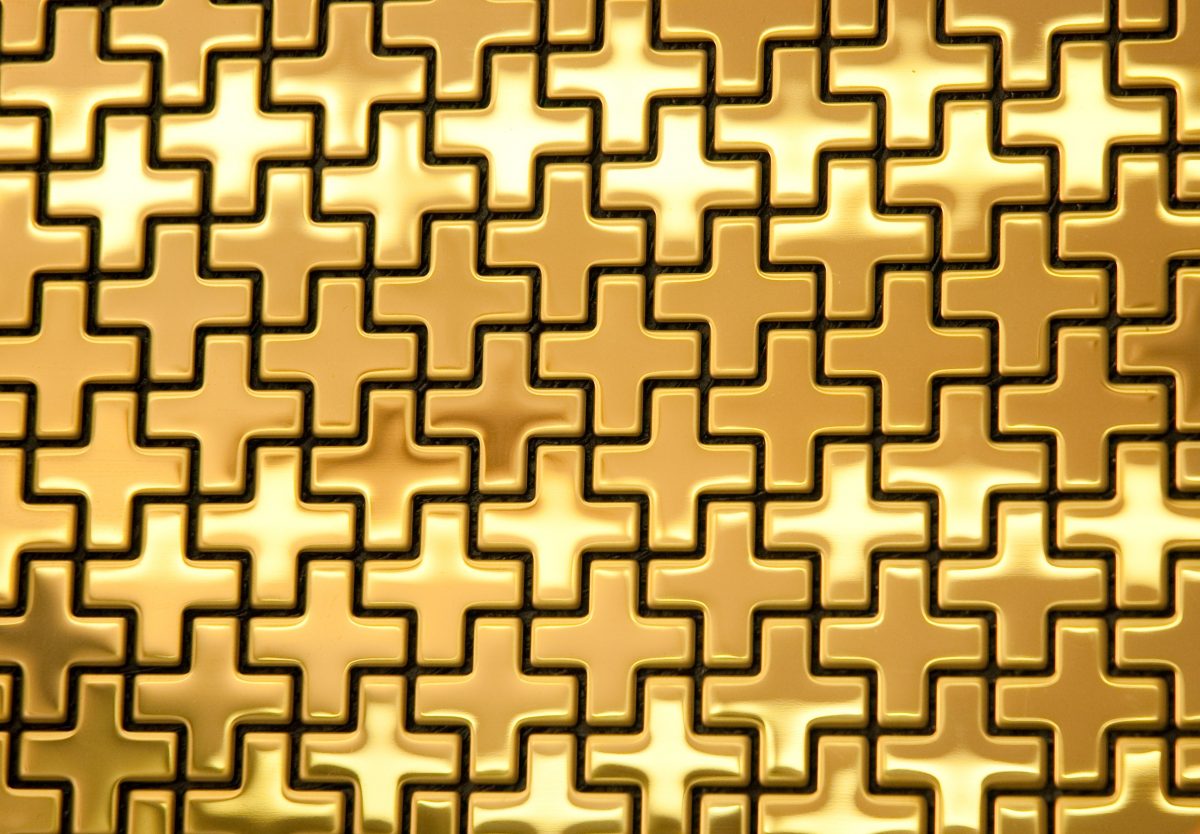

Punched from one sheet of 1.6mm metal, ALLOY tiles are made from solid metal and containno backing mesh, plastic inserts or metal look-alike ‘metallic’ coatings, so ALLOY tiles won’t dent, crack or de-laminate. Beware of imitations!

ALLOY has been producing metal mosaics for more than 10 years. ALLOY metal tiles are face mounted for better protection of the tile face during installation.

Stainless steel and other metal tiles cannot be cut on site without leaving sharp edges and burn marks, ALLOY is the only manufacturer to offer a full range of finishing pieces ensuring a superior finish when a full tile will not fit!

As ALLOY metal tiles are a premium product we want to ensure you are getting the right tile for the right situation along with the best the sales support possible, so before you contact us to purchase your ALLOY tiles, feel free to browse through our showcase or order samples online. If you need assistance at any time or contact us and we’ll get back to you within 24 hours.

No. ALLOY tiles are solid metal and are therefore very difficult to cut like regular ceramic tiles, particularly if you don’t have the right tools. Our metal tiles have been designed to provide a seamless finish and we don’t like to leave anything to chance. We have designed an extensive range finishing pieces to ensure the perfect installation.

We do not advise installing ALLOY tiles yourself. As ALLOY metal tiles are a premium tile product, we highly recommend using an experienced, professional tiler who is familiar with providing a high quality finish. Please contact us if you require the name of a suitable tiler in your area, we may be able to help.

No, however, if there is some appearance of ‘discolouration’ it is usually surface contamination that deposits ON the surface of stainless steel, this can be removed by cleaning using the above products and techniques.

As an end product stainless steel is 100% recyclable, durable and requires a minimum of maintenance, outlasting many competing products and eliminating requirements for additional potentially hazardous materials such as paint, fire protective coatings, cleaners and solvents. New stainless steel comprises at least 50% recycled stainless steel product and more than half the stainless steel produced today has already been another useful stainless steel product in the past.